Controller Kits And Components

Banlaw recommends using only Banlaw products to ensure compatibility. However, pre-existing hardware can be utilised if it is compatible with the Banlaw ResTrack Lite Controller. To check if your existing hardware is compatible with this device, please refer to the specifications table for each component within TBA.

BRTLC01A-* Controller Kit

The controller kit consists of:

- 1 x BRTLC01A - Banlaw ResTrack Lite Controller

- 1 x Power Supply or L coded connector

- 20 x BRTLC016 – Vehicle QR Tags

BRTLC01A

RTL Controller

BRTLC016

QR Code

BRTLPS**A

Power Supply

Standard Controller Kit

| Part Number | Description | Region |

|---|---|---|

| BRTLC01A-1 | Controller Assembly, ResTrack Lite, Code L Connector | ALL |

| BRTLC01A-2 | Controller Assembly, ResTrack Lite, Type I Power Supply | AU |

| BRTLC01A-3 | Controller Assembly, ResTrack Lite, Type B Power Supply | US/PHL |

| BRTLC01A-4 | Controller Assembly, ResTrack Lite, Type F Power Supply | EU/IDN |

ResTrack Lite Controller Kit part number BRTLC01A-1 should only be chosen if a reliable 12-24VDC power supply is available

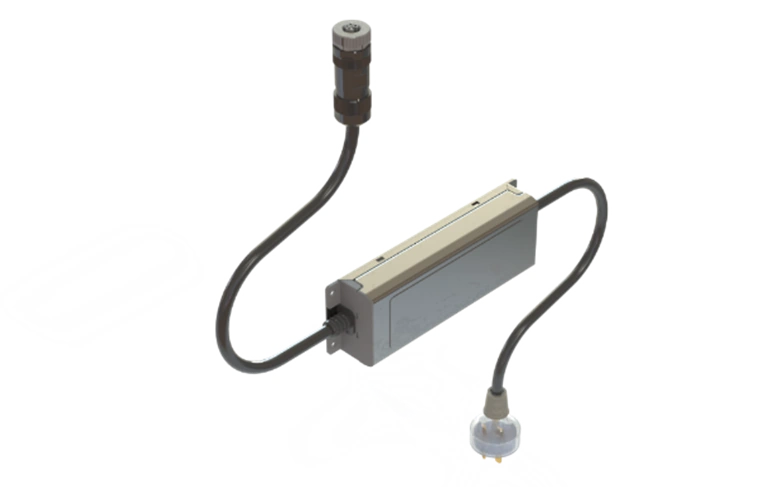

BRTLPS**A - Power Supply

The Banlaw ResTrack Lite Controller will be supplied as a kit with either a wirable plug for use cases where 12-24 VDC @ 4A is available, or a power supply compatible with standard power outlets.

BRTLPS01A – Power Supply Assembly, Type I

Banlaw supplied Power Supply Specifications as follows:

| Parameter | Value |

|---|---|

| Operating Temperature | -40°C (-40°F) to 80°C (176°F) |

| Input Voltage Range | 100-305 VAC |

| Output Voltage | 24VDC |

| Rated Power | 96W (4A @ 24VDC) |

| IP Rating | IP67 |

Field Wirable L Coded Plug (Banlaw P/N 001993) should only be chosen if an existing 12-24VDC @ 4A power source is available.

Field Wireable L-Coded Connector

Field wirable L Coded connector should only be used if an existing regulated 12-24VDC at Min. 4A power source is available.

Field Wirable L Coded Connector (Banlaw Part No: 001993)

Pinout diagram

| Pinout Diagram | Pin NO. | Description |

|---|---|---|

| 1 | +V |

| 3 | 0V | |

| 2, 4, 5 | Not in use |

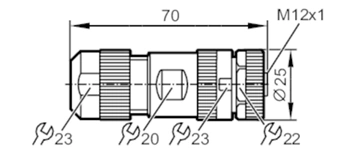

L Coded Connector Overall Dimensions & Tools Required

Input Power Specifications | |

| Input Voltage Range | Regulated 12-24 VDC |

| Rated Power | 40mA at 12VDC / 20mA at 24VDC |

Cable Specifications | |

| Wire gauge | Regulated 12-24 VDC |

| Cable sheath diameter | 40mA at 12VDC / 20mA at 24VDC |

General connector assembly procedure

- Strip the wires to expose 8mm of conductor.

- Place a bootlace ferrule on each core.

- Unscrew the compression gland and the body shell from the connector.

- Insert the +V wire into terminal 1 and tighten the screw.

- Insert the 0V wire into terminal 3 and tighten the screw.

- Screw the connector body into the connector.

- Tighten the compression gland.

- Tighten the body shell to ensure a secure fit.

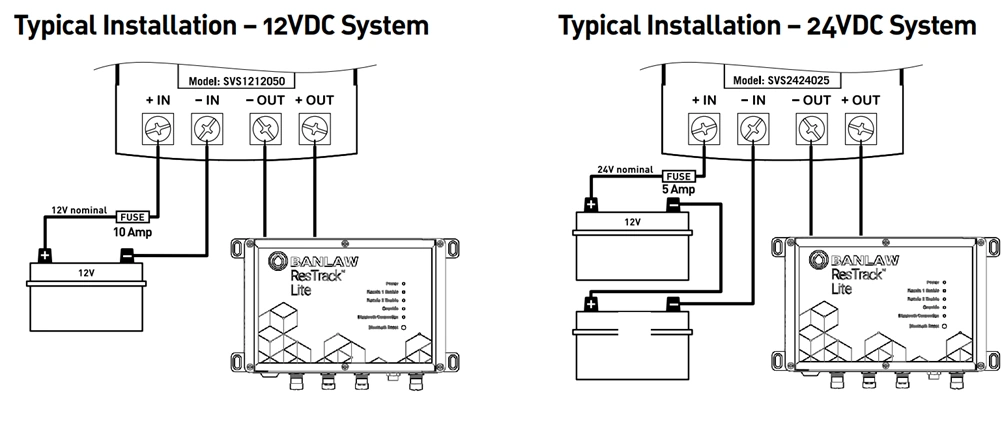

Voltage Stabilisers

In the absence of a regulated power supply, integrating a voltage stabiliser into the system can achieve a stabilised 12-24V DC output to ensure the controller is running in the optimal condition.

Voltage Stabiliser, 12V-12V DC, 000769

| Input Voltage | Part Number | Description |

|---|---|---|

| 11-17V | 000769 | Voltage Stabiliser, Intervolt, 12V-12V DC |

| 22-33V | 001932 | Voltage Stabiliser, Intervolt, 24V-24V DC |

Typical 12VDC or 24VDC Voltage Stabiliser Installation System

Please refer to manufacturer's installation & operation manual prior to assembly:

https://www.intervolt.com/wp-content/uploads/2015/07/interVOLT-SVS-Manual.pdf

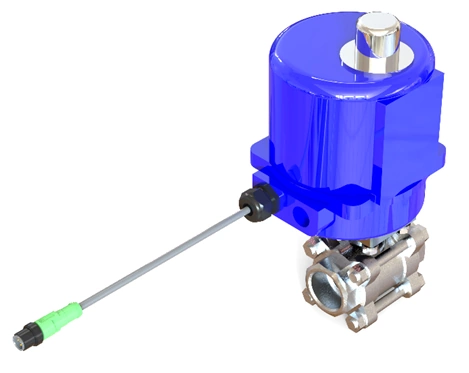

BRTLAV**A - Ball Valves

Banlaw ResTrack Lite Controller can control up to 2 Actuated Ball Valves or Flow Controlling devices. Banlaw ResTrack Lite Controller has been designed to interface with a GND-switched control actuated ball valve, shown above.

Actuated Ball Valve

In the event of a power failure this Actuator Valve will not fail closed. If a fail to close system is required, an alternate valve will need to be selected. Contact Banlaw for assistance in this regard.

Banlaw assembled Actuated Ball Valve electrical specifications as follows:

| Part Number | Description | Process Connection |

|---|---|---|

| BRTLAV01A | Valve, Ball, Actuated, 1” BSPT (F), OM-1, M12 Code A 5m, 24VDC | 1” BSP (F) |

| BRTLAV02A | Valve, Ball, Actuated, 1.5” BSPT (F), OM-1, M12 Code A 5m, 24VDC | 1.5” BSP (F) |

| BRTLAV03A | Valve, Ball, Actuated, 2” BSPT (F), OM-1, M12 Code A 5m, 24VDC | 2” BSP (F) |

| BRTLAV04A | Valve, Ball, Actuated, 1” NPT (F), OM-1, M12 Code A 5m, 24VDC | 1” NPT (F) |

| BRTLAV05A | Valve, Ball, Actuated, 1.5” NPT (F), OM-1, M12 Code A 5m, 24VDC | 1.5” NPT (F) |

| BRTLAV06A | Valve, Ball, Actuated, 2” NPT (F), OM-1, M12 Code A 5m, 24VDC | 2” NPT (F) |

Alternate Ball Valve Actuator Pinout Diagram

A pre-existing 24VDC actuated ball valve can be controlled by ResTrack Lite controller. Refer to the pinout table below for the termination details for an alternate Actuated Ball Valve.

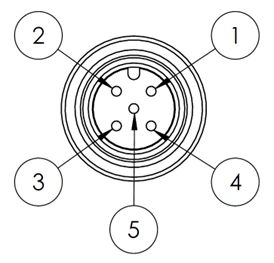

| M12 Connector Pinout Diagram | Pin NO. | Description |

|---|---|---|

| ||

| 1 | +V | |

| 2 | OPEN | |

| 3 | 0V | |

| 4 | CLOSE | |

| 5 | Unused |

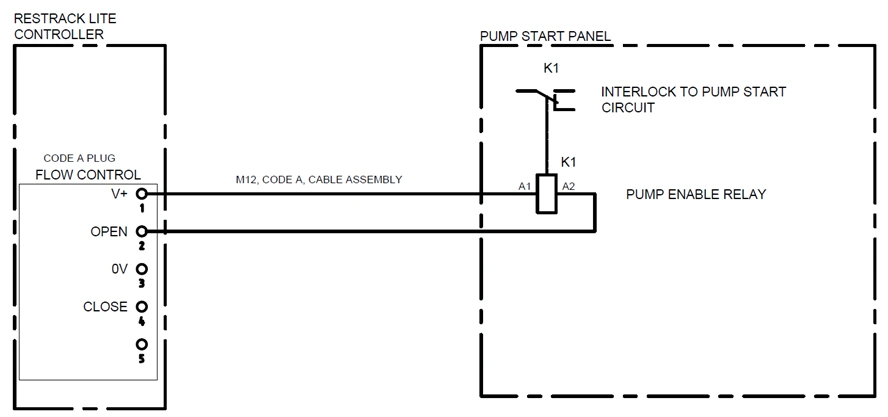

Generic Pump Start Pinout Diagram

Ball valve control circuit can be used to control pump enable signal instead. A control signal can be either 24VDC or 0V. Depending on configuration, connect either Pin 1&2 or 2&3. Refer to the pinout table and diagram below for a generic termination diagram.

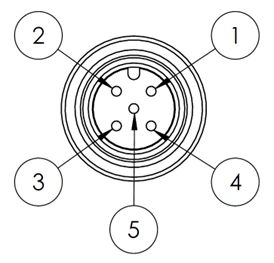

| M12 Connector Pinout Diagram | Pin NO. | Description |

|---|---|---|

| ||

| 1 | +V | |

| 2 | OPEN | |

| 3 | 0V | |

| 4 | UNUSED | |

| 5 | UNUSED |

Generic Pump Start Electrical Diagram

BRTFLM**A - Flow Meters

Flow Meter

Banlaw ResTrack Lite Controller can read up to 2 Hall Effect Flow Meters.

The flowmeter must be mounted so that the rotor shafts are in a horizontal plane. This is achieved by mounting the meter so that the terminal cover is facing in a horizontal direction.

Banlaw assembled Flow Meter electrical specifications as follows:

| Power Input | 12 - 24 VDC |

| Signals | 24V 0V Signal |

| Switch Type | Hall Effect |

The range of Flow Meters offered by Banlaw:

| Part Number | Description | Process Connection | Max Pressure | Max Flow rate |

|---|---|---|---|---|

| BRTLFM01A | Flowmeter, Hall Effect, 1” BSPP (F), M12 Code A | 1” BSPP (F) | 68 bar (1000 psi) | 150 lpm (40 gpm) |

| BRTLFM02A | Flowmeter, Hall Effect, 1.5” BSPP (F), M12 Code A | 1.5” BSPP (F) | 30 bar (440 psi) | 250 lpm (66 gpm) |

| BRTLFM03A | Flowmeter, Hall Effect, 2” BSPP (F), M12 Code A | 2” BSPP (F) | 20 bar (300 psi) | 450 lpm (120 gpm) |

| BRTLFM04A | Flowmeter, Hall Effect, 1” NPT (F), M12 Code A | 1” NPT (F) | 68 bar (1000 psi) | 150 lpm (40 gpm) |

| BRTLFM05A | Flowmeter, Hall Effect, 1.5” NPT (F), M12 Code A | 1.5” NPT (F) | 30 bar (440 psi) | 250 lpm (66 gpm) |

| BRTLFM06A | Flowmeter, Hall Effect, 2” NPT (F), M12 Code A | 2” NPT (F) | 20 bar (300 psi) | 450 lpm (120 gpm) |

It is recommended to install a filter or a Y-Strainer inline before the flow meter to prevent particles from jamming the rotors.

ResTrack Lite Controller is limited to receive signal only from Hall Effect Flow Meters.

Generic Hall Effect Sensor Pinout Diagram

ResTrack Lite system can receive flow signal from pre-existing flowmeter, provided that it satisfies the following requirements:

- Output type: 3-Wire Hall Effect sensor

- Power: 24 VDC

Refer to the pinout table below for the termination details of a generic hall effect Flow Meter.

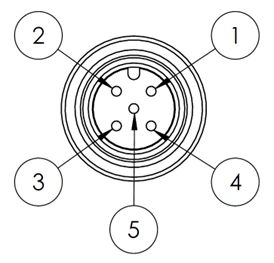

| M12 Connector Pinout Diagram | Pin NO. | Description |

|---|---|---|

| ||

| 1 | +V | |

| 2 | UNUSED | |

| 3 | 0V | |

| 4 | UNUSED | |

| 5 | FLOW SIGNAL |

Y-Strainer

To ensure optimal Flow Meter performance and longevity, It is recommended to install a 100mesh (150 micron) strainer prior to the flow meter.

Y-Strainer

Below are the Y-Strainer options and part numbers offered by Banlaw:

| Part Number | Description | Process Connection | Mesh Size |

|---|---|---|---|

| 001999 | Y Strainer, 1" BSPT, SS, 150um | 1” BSPP (F) | 100 mesh / 150um |

| 001998 | Y Strainer, 1-1/2" BSPT, SS, 150um | 1.5” BSPP (F) | 100 mesh / 150um |

| 001997 | Y Strainer, 2" BSPT, SS, 150um | 2” BSPP (F) | 100 mesh / 150um |

| 001996 | Y Strainer, 1" NPT, SS, 150um | 1” NPT (F) | 100 mesh / 150um |

| 001995 | Y Strainer, 1-1/2" NPT, SS, 150um | 1.5” NPT (F) | 100 mesh / 150um |

| 001994 | Y Strainer, 2" NPT, SS, 150um | 2” NPT (F) | 100 mesh / 150um |

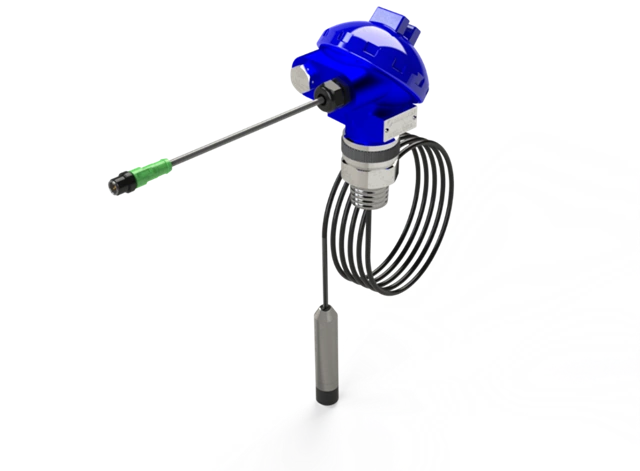

BRTLLS01A Level Sensor

Banlaw ResTrack Lite Controller can be connected to a 4-20 mA Level Sensor for tank level sensing.

Level Sensor

RTL Controller only supports 1 fuel tank/level instrument. If more than 1 tank or fluid type is being used, a second controller will be required.

Refer to assembly procedure for the termination diagram, BRTLLS01A Level Sensor Installation Procedure.

Banlaw Level Sensor specifications are as follows:

| Parameter | Value |

|---|---|

| Power Input | 12 - 24 VDC |

| Signals | 24V, 0V |

| Feedback Type | 4-20 mA signal |

| Process Connection | 1” BSPT (M) |

| Max. Depth | 5 m / 16.4 ft |

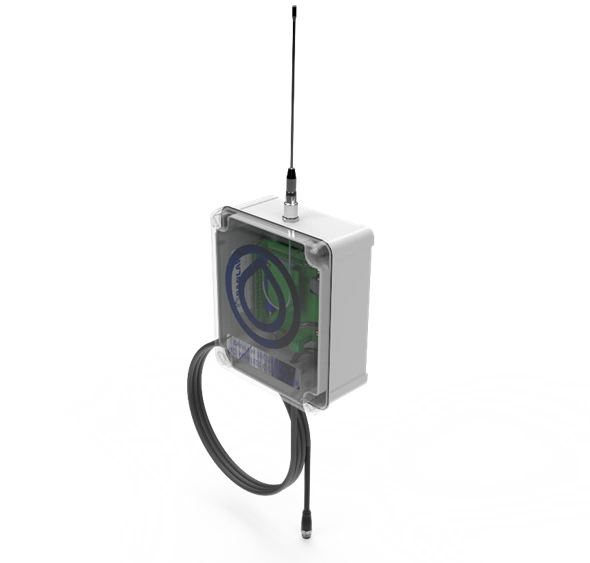

BRTSFL101 Banlaw SecureFill Auto ID

Banlaw SecureFill is the most secure vehicle identification system available for ResTrack Lite. It is comprised of a gateway, wireless nozzle reader and a tag. In case of LV nozzle, tag is close proximity RF (radio frequency), and HV - embedded into Dry Break receiver. Each tag is associated with a vehicle, allowing secure automatic identification on contact or proximity.

The Wireless Controller is the communication hub for the SecureFill Wireless Auto ID system. The Wireless Controller is compatible with the SecureFill Wireless Splash Fill and Dry Break systems and allows communication between a Nozzle Reader and Banlaw ResTrack Lite Controller.

This system will only communicate with SecureFill (HID identiTAG) equipment and is not compatible with Orpak Wireless components.

A single gateway is required for each Auto ID enabled ResTrack Lite controller.

BRTSFL101 ResTrack Lite Auto ID Gateway

Banlaw SecureFill Auto ID Gateway specifications as follows:

| Technical Specification | SI Units | Imperial Units |

|---|---|---|

| Operating Temperature | -25°C < T < +60°C | -13°F < T < 140°F |

| Unit Dry Weight | 741 g | 1.63 lbs. |

| Range | 40 m | 131.2 ft |

| Antenna Frequency | 433.92 MHz | |

| IP Rating | IP67 |

Banlaw SecureFill Auto ID System

SecureFill Auto ID provides an automatic vehicle recognition. This form of identification is the highest security that ResTrack Lite offers. Contact a Banlaw representative if you are unsure about what type of solution should be implemented for your use case.

A single base station BRTSFL101 can support up to 2 nozzles of any type.

High Flow Dry Break Wireless Auto ID System

Banlaw ResTrack Lite Controller is compatible with Banlaw SecureFill Dry Break Auto ID Wireless Swivel for a higher level of security when a base station (Banlaw Part No #BRTSFL101) is connected to the BRTLC controller. This wireless technology enables a higher level of security that is compatible with Banlaw Dry Break Auto ID products. Acting as both a conventional swivel and an identification interface to the ID tag within the receiver. The Auto ID Wireless Dry Break System ensures secure contact-based identification and is compatible with Banlaw Auto ID Nozzles and Receivers

BRT3*WSA SecureFill Dry Break Wireless Swivel

Low Flow Splash Fill Wireless Auto ID System

Banlaw ResTrack Lite Controller is compatible with Banlaw Splash Fill Wireless ID system for automatic vehicle identification. It uses a short-range RFID tags to transmit unique identifiers from Splash Fill nozzles to the base station BRTSFL101.

BRTSFL200 SecureFill LV Nozzle

Connection Cable, 5m, M12, A Code, Straight (M) Straight (F)

M12 A Coded extension cable is available if the pre-terminated cable assembly is too short. This extension cable can be used for either of the process connections, excluding SecureFill Auto ID Gateway.

001992 A Coded Extension Cable

Extension cable specification as follows:

| Part Number | Description | Process Connection |

|---|---|---|

| 001992 | Connection Cable, 5m, M12, A Code, Straight (M) Straight (F) | M12 A Coded Connector |